How to keep your onshore geotechnical laboratory testing programme on track

High-quality data from laboratory testing is critical for characterising the physical properties of soils. These data are vital for delivering reliable and efficient foundation designs to support the offshore structures we will all increasingly rely on to sustainably deliver our energy needs.

With increasing demand and a supply-constrained market, the challenge for developers and designers is how to mitigate project exposure to schedule delays caused by the late delivery of the geotechnical data needed to meet project milestones.

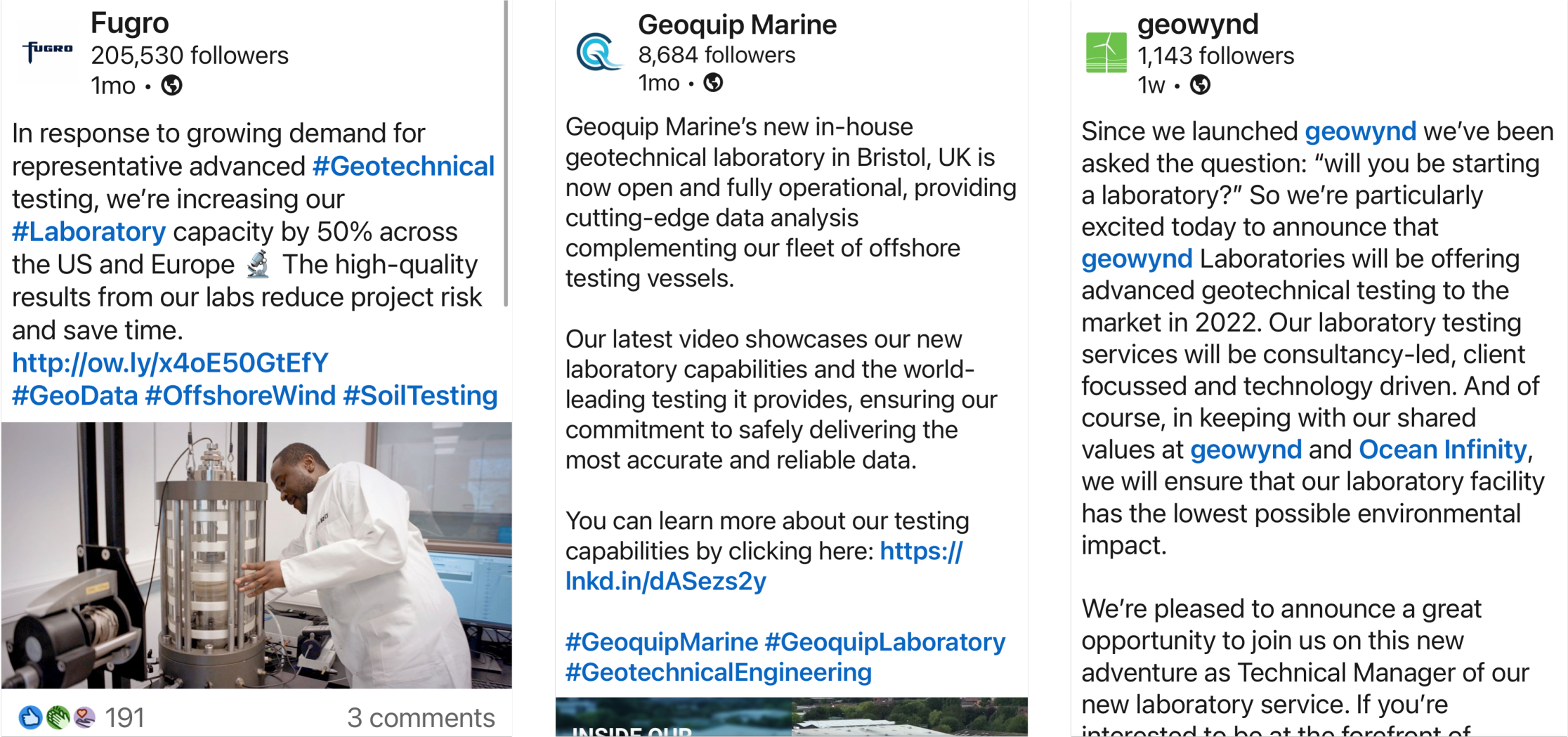

The supply-side of the industry is reacting to changing market dynamics by increasing capacity, as recent LinkedIn posts show:

These developments are welcome, but, like opening a new lane on the motorway, it’s likely this capacity will be quickly swallowed-up and most clients will face the same challenges as before.

Part of the reason why projects face these challenges is due to inadequate strategic planning at an early stage in the site investigation life cycle. A strategic and pragmatic approach, considered early in the site investigation planning stage can significantly reduce project exposure to the risks posed by poor performance during the laboratory testing phase.

How can projects influence the process and improve outcomes?

Here are five levers for taking control of your laboratory testing destiny:

1. Contractor Engagement

Contractor engagement and collaboration are key. In most cases, the site investigation contractor will either be performing the laboratory testing or managing the outsourcing of the testing to third party laboratories, or a combination of the two.

Use the Invitation To Tender (ITT) process as an opportunity to engage with the contractors and start a conversation to inform your testing strategy and tactics. The formality of the ITT process provides a useful documented reference baseline for the performance expectations once the contract is awarded.

Throughout the execution phase of the site investigation, ensure laboratory testing, laboratory capacity, bottlenecks, anticipated test types and volumes based on actual soil conditions encountered are on the agenda for discussion during the weekly meetings. This will help forestall issues before they become a problem and/or identify them early enough for solutions to be worked.

2. Contract

Financial penalties demonstrably influence contractor behaviour. It’s not an approach for everyone. Whether it’s a tactic you choose to employ or not, it’s good to be aware that your programme could be impacted by the actions of others and have mitigation measures in your arsenal should it become an issue. I know from experience how frustrating it can be when your programme is pushed down the queue to prioritise another client who has the option to apply performance penalties.

3. Project Management

It’s project management 101 but try to keep your feedback into the process off the critical path as much as possible by providing input and responding to laboratory-related queries promptly.

From the outset, ensure laboratory testing and reporting feature as regular items on the agenda for the weekly progress and planning meetings. This clearly communicates that the onshore laboratory and reporting phase is an important element of the project and creates opportunities for potential issues to be identified before they pose a threat to the schedule.

4. Phasing

A phased testing and delivery framework aligned around project stage gates (i.e. delivery schedules based on need) can help to alleviate the pressure on all parties and avoid the stress and friction caused by setting arbitrary timelines based on so-called ‘norms’. For example, break the testing requirements down into standard and advanced testing and explore what more can be done offshore to characterise the soils. Align delivery of results with the project stage gates; develop agile plans that allow the contractor some flexibility to manage and deliver data when it’s needed – ‘just-in-time’ strategies are commonly adopted in complex and time-critical manufacturing processes.

5. Technical Optimisation

Consider whether more lab testing can be performed offshore and optimise the collection of indirect geotechnical datasets.

Where possible, use difference or validation models to leverage existing or offset advanced datasets alongside the project ground model to rationalise testing around ‘proven’ and ‘unproven’ engineering units.

Avoid over-specification – challenge whether the planned suite of tests deliver value for money.

Innovation - explore new testing techniques and novel technologies which perhaps fall outside of the established standards but are likely to be fit for most purposes and deliver schedule benefits e.g., optical PSD detection techniques.

--

At Inosys, we think deeper and go further to help offshore energy businesses optimise the performance of the geophysical and geotechnical resources available to them and deliver success stories time after time.

Please do get in touch to discuss how we can help optimise your laboratory testing programme and all things offshore geo-related to keep your project on track

- 25th November 2021